How do you unlock the potential of battery energy storage before you even turn it on? In this blog post we’ll talk about the critical role of Commissioning Services in ensuring timely and cost-effective project delivery.

Finding a partner you trust can be a challenge in such a new and diverse market. But here at FlexGen, we have established a solid reputation in commissioning a wide range of new products across various applications for over ten years. In fact, our team has been commissioning energy storage since 2009 when we got our start providing critical load, 50kW microgrids to remote locations for the US Military. By 2014 we were installing and integrating 1MW behind-the-meter microgrids. A few years later in 2018, we would be installing 10MW medium scale, distribution level, energy storage systems with energy trading, and black start capabilities. Today, we are providing large scale, some even 530MW+ energy storage solutions combined with our best-in-class EMS software, HybridOS, to help our clients realize the most value from their energy investments.

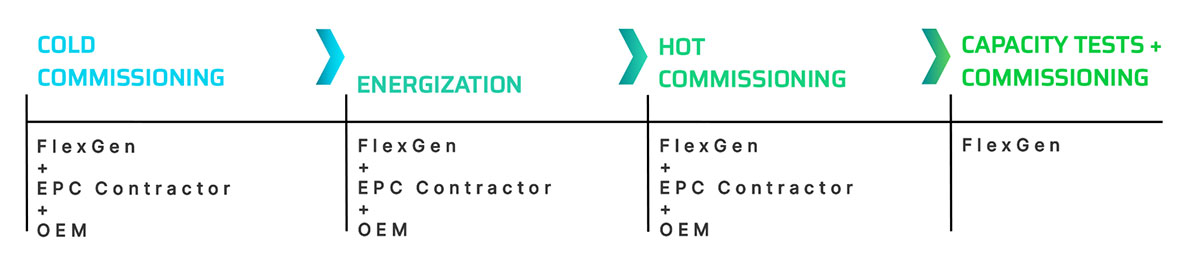

Commissioning of every battery energy storage project follows the stages outlined below to validate accuracy of construction, functionality of equipment, safety and readiness for operation, and finally performance of the completed system.

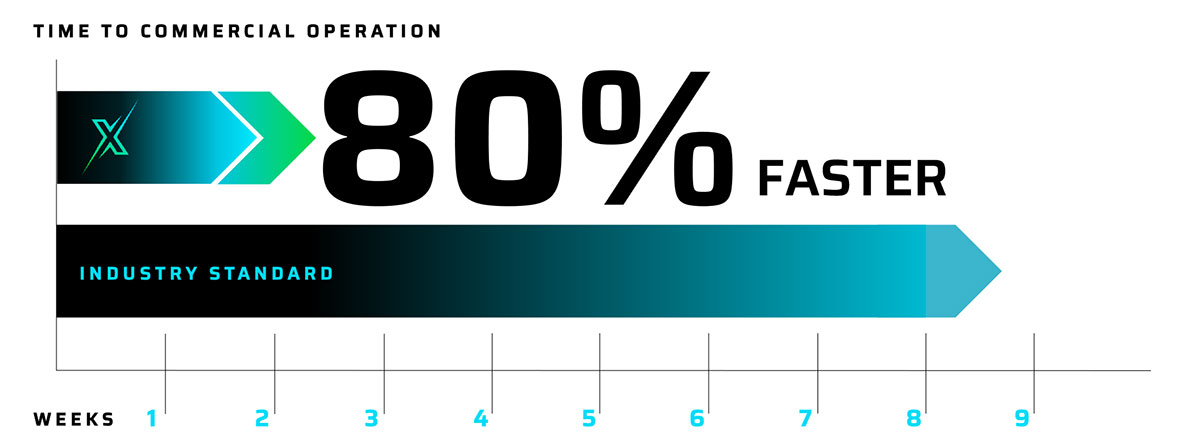

Our primary objective is to streamline the commissioning process, enabling you to fully concentrate on maximizing value for your members. Understanding the significance of swift interconnection, we have perfected the art of commissioning sites in just 14 days, a remarkable feat compared to the industry average of approximately 60 days. Here’s how we achieve this seamless efficiency…

By shipping a complete block of your chosen inverter and battery systems to the FlexGen Innovation Lab in Durham, NC for advanced testing and pre-commissioning, we optimize the HybridOS controls for the specified OEM system.

The configured Local & Site controllers are tested via FlexGen control emulators to validate functionality and performance.

This process resolves any issues with the configuration on the HybridOS controller or the OEM controllers ahead of deployment to site.

This also provides an opportunity for the EPC Contractor to gain experience with the equipment ahead of cold and hot commissioning on the site.

In the dynamic realm of the power grid, demands are ever-changing. Adapting to evolving regulations, staying up-to-date, and meeting shifting standards have become crucial imperatives.

At FlexGen, we wholeheartedly invest in foreseeing your future requirements and proactively tackling them. By shouldering the burden on your behalf, we liberate you to concentrate on your core business pursuits. With our steadfast commitment to innovation and reliability, you can trust us to keep you ahead in the energy landscape, allowing your organization to thrive.

Embrace the future with confidence, knowing that FlexGen has got your back.